-

X-Guard | マシンガード・安全柵

X-Guard | マシンガード・安全柵

アクセレントはスウェーデンの安全柵メーカーです。パネルの取り付け・取り外しがとても簡単で、世界中の工場や倉庫で使用されています。ISO・JISに準拠しており、安全で安心な環境を整えることができます。

-

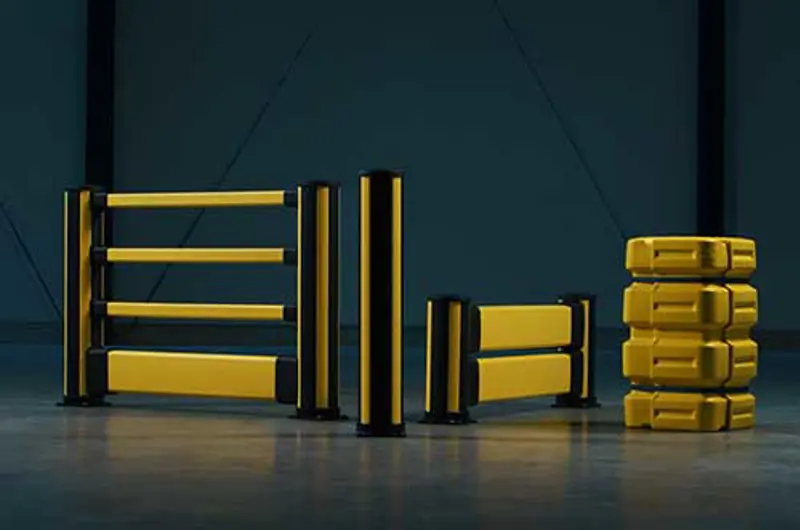

X-Protect | 衝撃吸収・衝突防止システム

X-Protect | フォークリフトガード

X-Protectは、アクセレントの新しい衝撃吸収・衝突防止のためのフォークリフトガードやボラードなどの製品シリーズです。倉庫や工場に必要なあらゆる衝撃保護製品を提供します。モジュラー方式により、自由自在の組み合わせが可能。拡張やレイアウト変更にも素早く対応できます。

-

倉庫用パーティション

工場および倉庫環境用メッシュパネル

アクセレントは工場や倉庫環境用メッシュパネルのリーディングカンパニーです。当社製品とシステムは、図面作成の準備段階から最終製品の組み立てにいたるまで、全ての段階で柔軟かつ迅速なソリューションをお約束いたします。

転落防止用製品