What do the updates of EN 528 and EN 619 mean for the industry?

The importance of early, systematic, and detailed risk assessment is highlighted by the new standards, as is systematic verification and validation of the safety measures taken. Clear and strict rules are set regarding perimeter guarding (fencing), monitoring of access doors and presence sensing inside hazard areas. EN 528 also focusses on operating modes and safe change from one mode to the other.

The new EN 619 will introduce an “area concept” subdividing conveying systems into public and traffic areas, working places, restricted and danger areas. It deals heavily with safety at the entry/exit points to hazard zones for both persons and transported loads. The size of in/out openings and of guards limiting access to hazard zones will be updated and specified more precisely.

EN 619 also seeks to include safety requirements for new technology introduced in conveying and storage systems such as transfer cars, vertical transfer devices, tote conveyors, and destination coded vehicles.

How can Axelent support you?

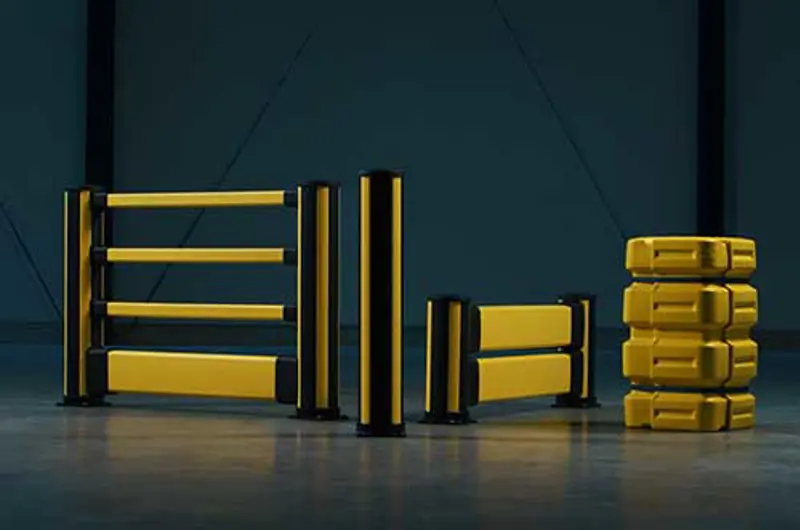

Axelent offers much of the equipment needed to ensure safety in such environments: fencing and doors, entry/exit gating, guard railing for walkways and fall protection for mezzanine floors, as well as suitable locks.

For instance, EN 528 requires that access doors open to the outside only and that it must be possible to open the lock from outside with a key only, but without a key from the inside at any time. These requirements are met by our different X-It lock solutions and among those the electric lock with escape release function. However, an interlocking switch will always have to be added to the X-It lock.

Related standards you may want to check out:

EN ISO 11161:2010 - Integrated manufacturing systems - Basic requirements (currently under revision). This standard contains detailed requirements and helpful hints for the safety of systems made up of several machines, robots, and conveyor systems. It particularly helps control system designers to ensure safety of operating modes, access to hazard zones, and troubleshooting/maintenance “on the fly”.

ANSI B11.20:2017 - Safety Requirements for the Integration of Machinery into a System. Though this is an American standard not applicable in the EU, it is more up to date than the current ISO 11161:2010 and will thus be helpful for designers of IMS. Much of its innovations will be adopted by the revision of ISO 11161.

ISO 3691-4:2020 - Industrial trucks - Safety requirements and verification - Part 4: Driverless industrial trucks and their systems. This new standard also deals with driverless robot-type carriages lifting and transporting totes between unmanned storage areas and order picking/commissioning workplaces.

EN ISO 24134:2018 - Industrial trucks - Additional requirements for automated functions on trucks

ANSI/ITSDF B 56.5:2019 - Safety Standard for Guided Industrial Vehicles and Automated Functions of Manned Industrial Vehicles

ANSI/RIA R 15.08-1:2020 - Industrial Mobile Robots - Safety Requirements - Part 1: Requirements for the Industrial Mobile Robot

EN ISO 13482:2014 - Robots and robotic devices - Safety requirements for personal care robots

_________________________________________________________________________________

¹ Type C standards contain safety requirements for a particular product or product group. For more information on the structure of safety standards see link to: