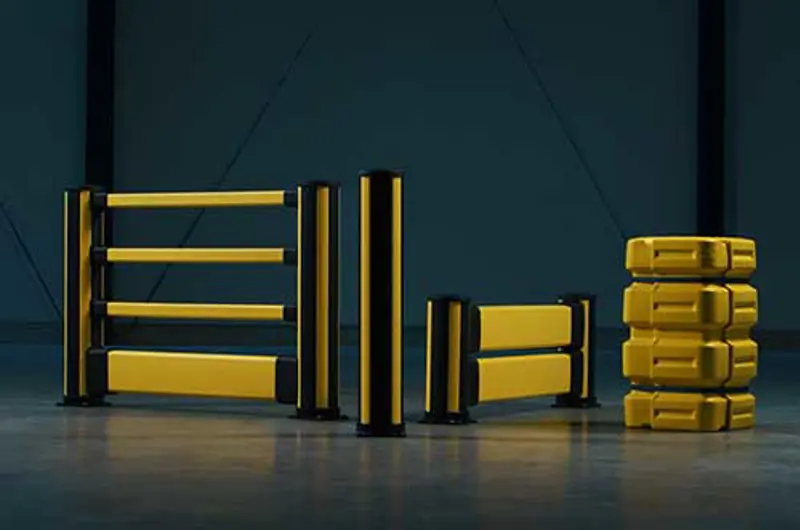

A long-term partnership between Axelent and Inca Plast became the basis for X-Protect

"Our collaboration with Axelent began in 2016 through a collaboration with another supplier. Then we started making the top plug that sits at the top of the posts for Axelent's machine protection solutions, as well as the foot cover at the bottom of the post. After that, we quickly became involved in Axelent's product development and today we make most of the injection molded parts for Axelent.

Even though Axelent has grown and become as large as the company is today, I feel that the family feeling and the simple collaboration endures. You can visit each other's workplaces and have a cup of coffee and speculate about new projects. Which has contributed to making it very easy to work together. I feel that there is an openness and honesty between the companies and always a straight sincerity. Everyone wants to achieve the best possible results. The fact that we then have the geographical proximity by the fact that we are both in Hillerstorp also makes it easier of course."

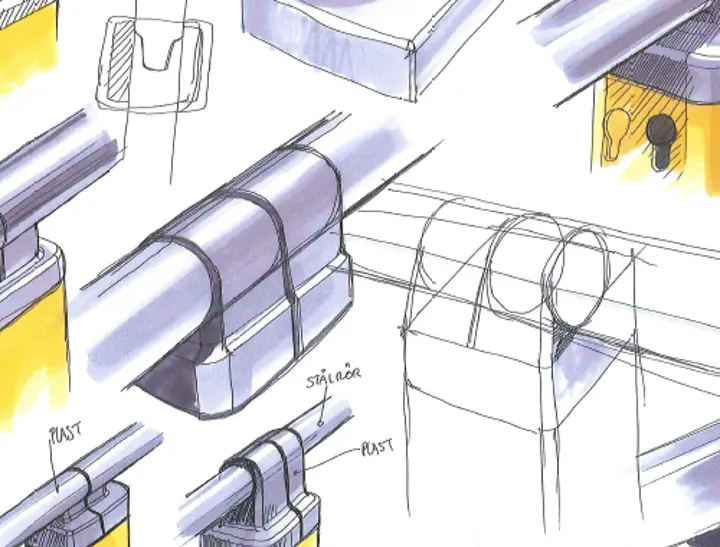

The importance of being involved at an early stage in the design phase of the project

"We came in contact with the project when Johan Axelsson, one of Axelent's owners, told us about a new upcoming product range that they envisioned where they would extrude products. I then jokingly suggested that we must do the project in collaboration. It took a while before I realized that he had actually picked up on that suggestion.

It was incredibly inspiring to be trusted to do something that we had not done before and we helped out to set up a completely new form of manufacturing. I saw it as a proof of what Axelent has appreciated with our partnership over the years and that they wanted to make this venture together, which we have indeed done.

We have done this entire process completely together from the start to finish line with everything from finding the right partner and machine supplier to the development of the products. The method of extrusion was completely new for us as a company, even though we know injection molding. Sometimes I think that it might be lucky that both we at Inca and Axelent were new in this area. If you had known in advance all the challenges and hardships, you might never have dared to invest. But the challenges have been worth it, as well as the courage and strength to persevere, because we see the result today - a really good innovative product. It has always been the starting point, that the focus is not on the commercial, but that it should be the best possible product. It has been continuous learning from both sides, and the difficulties we have encountered have largely been due to Axelent really stretching the bow and aiming for a goal they set around high quality and strength of the product, without backing down.

Obviously it has been difficult many times, but also a lot of fun during the process. It’s always joyful working with Axelent. After all, there have been infinite number of courageous meetings, but with a good tone and a positivity. It has been inspiring to work with such a complex product, as there are many things that must be coordinated.

We got to be part of delivering the whole solution and to be part of the journey from start to finish. Being able to make the journey together with both customers and partners is what we at Inca are passionate about."